Introduction

Part A is high density spray blend polyols, it reacts with Part B--isocyanate to produce

foam which has excellent performances, which are as follows.

Fine and uniformity cells.

Low thermal conductivity.

Perfect flame resistance

Good low temperature dimensional stability.

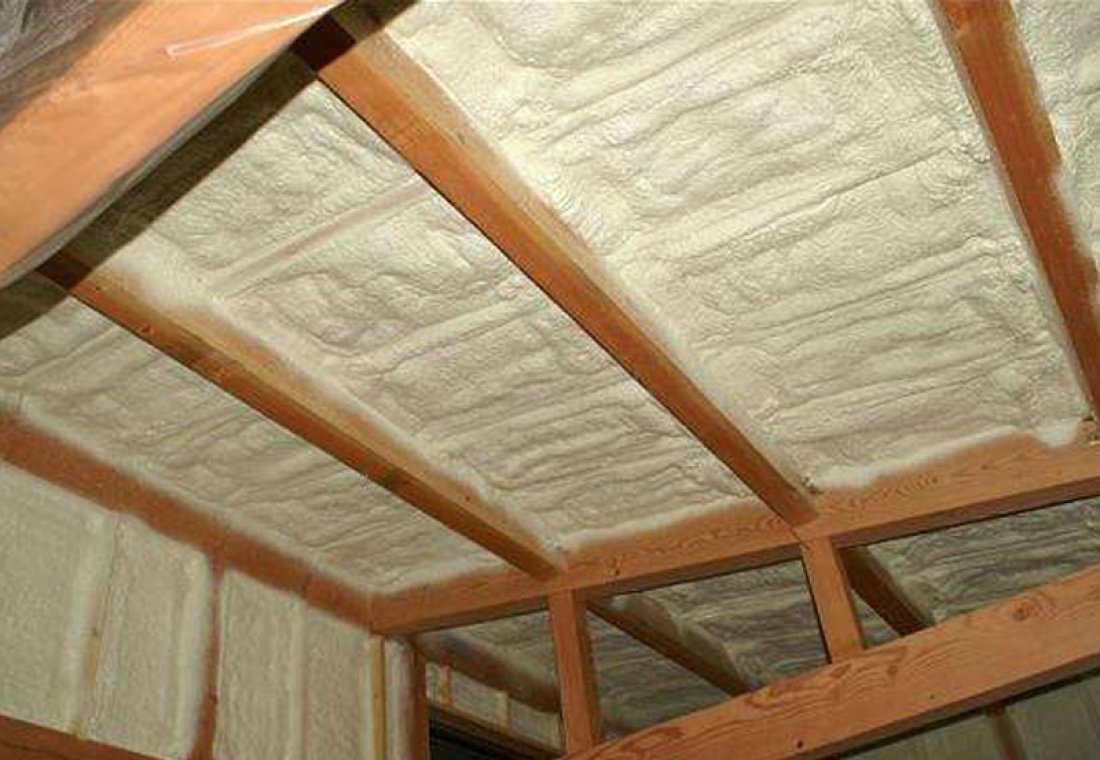

It applies to all kinds of thermal insulation engineering which use the spray technology, such as cold storages, pot, large-scale pipelines, construction roofs and all types of abnormity thermal insulation projects.

CERTIFICATE OF ANALYSIS

Product Type |

DHK-30 | ||||

Origin |

Qingdao |

Quantity |

0.44T | ||

POL/ISO ratio(weight) | 1:1.0 | ||||

Test Conditions |

Specification |

Result | |||

Ambient temperature 24 ℃ |

Cel Time 3-5 s |

3 | |||

Material temperature 16 ℃ |

Gream Time 6-10 s |

9 | |||

Stiring time 3 s |

TFT / s |

/ | |||

Stiring Rpm 8000 r/min | Free Density 23.5-40 kg/m3 |

35.1 | |||

Conclusion |

Qualified | ||||