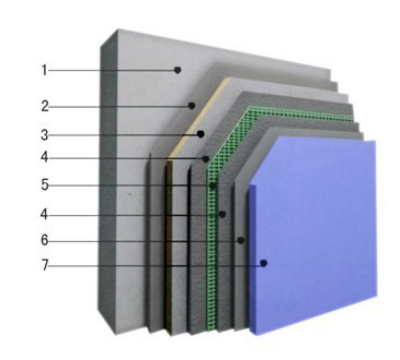

Structure

1- base course wall

2- 2-adhesive mortar

3- 3. YGHY PU composite panel

4.anti- crack mortar

5. alkali- resistant mesh

6. exterior wall putty

7. exteriorwall coating

Performance:

Item | performance | |

PU core material | (Kg/m³) Density | ≥32 |

(W/m·k) Thermal conductivity | ≤0.022 | |

% Water absorption | ≤3 | |

PU composite panel | %(70±2℃,48h) Dimensional stability | ≤1 |

(Kpa) Compression strength | ≥150 | |

Flammability | B1 | |

(mm)Deflection | ≥6.5 | |

(Mpa)Tensile strength when perpendicular to the surface | ≥0.10 Failure occurs in the core material | |

Constructionprocess

The construction process of PU thermal insulation panel system forexterior wall is the same as that of EPS boards.

Product Features

1、 Optimal insulation property。

The thermal conductivity of polyurethane foam panel is the lowest ofall the insulation materials, and can easily meet the target of energy-saving75%.

2、Fire safety

Rigid PUfoam belongs to thermosetting material, and the flame- retardant polyurethanedoes not have the property of flame spread. According to the fire test, thereis no need to set fire barriers.

3、Safe construction。

Both sides ofthe PU panel are cement-based. When it is affixed to the base course wall with decorativemortar, it will never fall off.

4、Simple process& high efficiency

5、Stableperformance& durability

6、High economic efficiency

Wall thickness is reduced by25px, will increase 0.2% -0.3% of the indoor area, thin polyurethane compositeboard material, high economic efficiency.